We are Jente and Mette, two enthusiastic food technology students from the Netherlands, and last year we had an exciting adventure at Naranjas del Carmen. Our hearts beat for education, food, and technology, and our journey led us to this ecological farm in Betera, Spain. Our project, and thus our goal, was to create a new product. It is an quite exciting process and we are happy to share it with you, starting from our first idea to the final product.

Step 1: Market Research

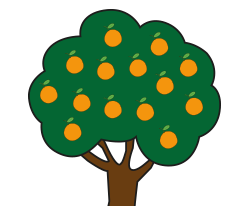

We dived deep into the market and did some research and brainstorming. We sifted through ideas, considered what people want, and aligned it all with the philosophy of Naranjas del Carmen. At Naranjas del Carmen, we’ve encountered a challenge with certain fruits that aren’t suitable for shipping due to irrigation issues or overripeness, especially with our pomegranates that have split open. Rather than allowing these fruits to go to waste at the farm, we’ve brainstormed creative ways to repurpose them, minimizing food waste.

Our commitment to sustainability drives us to explore innovative solutions for salvaging produce that would otherwise be discarded, aligning with our philosophy of reducing food waste from farm to table. Through these efforts, we aim to inspire others to rethink waste and embrace resourcefulness in tackling food sustainability challenges.

Step 2: Coming up with Ideas and Trying Recipes

Once the groundwork was set, it was time for some creativity. We crafted recipes that defined these amazing products. Here we followed the motto: less is more. Just like the other subproducts, we also wanted to create a product that contained few and only natural ingredients. Each step was written down so that the recipe could be reproduced by anyone at any time.

Because we had a lot of pomegranates that we were not able to ship, our aim was simple: create a delectable and enduring pomegranate recipe that encapsulated the fruit’s taste while ensuring its longevity. Rather than letting our fruits go to waste, we embarked on an experiment to transform them into something delightful and shelf-stable.

Step 3: The Testing-Phase

Now, the exciting part! We were in the testing phase, where we tried out versions of these products. Sometimes they turned out amazing, other times… well, let’s just say there was room for improvement. Every detail mattered, and we documented everything.

Step 4: Getting Production started

From our cozy test kitchen at the Finca to a factory nearby. Here the journey of our internship ended, and we left our notebook full of ideas and the feedback of the first test round to Gemma, who is in charge of the creation of subproducts. But we are willing to tell you how the process keeps on going. Here’s where perfected recipes meet the reality of big machines.

Step 5: The Finishing Touches

Imagine the subproduct packed in our eco-friendly carton with a plastic free-label that tells you everything you need to know. The label includes ingredients, nutritional tidbits, shelf life, and basically all you need to know.

Overall, we and the Naranjas del Carmen’s team see an opportunity in every fruit to prevent food waste. Therefore, we won’t stop being creative and are excited about every new byproduct.

My account

My account